Written by Martha Capwell Fox, DLNHC Historian

When we talk or write about the industrial history of the Heritage Corridor, we devote a lot of words to companies that no longer exist. Too often we overlook the stories of the ones that were born, built, or moved here, grew here, and are still flourishing. The return to the Lehigh Valley of F.L. Smidth and its continuing manufacture of the revolutionary Fuller-Kinyon pump inspired this list of heritage industries that have done business for decades– or even centuries –in the Corridor.

From oldest to (relative) newcomers:

C.F. Martin & Co.

The first Christian Frederick Martin, a German immigrant, began building guitars in Manhattan in 1833. In 1839, he moved to Nazareth. Martin Guitars is known for innovations such as the 14-fret neck and the “Dreadnought” guitar which became one of the standard acoustic guitar shapes. Still made almost entirely by hand- which you can watch by booking a tour of the factory- Martin acoustics are world-famous and have been favorites of musicians ranging from Hank Williams and Johnny Cash to Kurt Cobain, Paul McCartney, and Ed Sheeran.

Phoenix Forging Company

The forging plant on Catasauqua’s Front Street began as the Bryden Horseshoe Works in 1882, producing horseshoes in a new way—a single process that used a heavy hammer to make a completely formed shoe, including the heel and toe caulks. Bryden was one of the largest industrial employers in the Lehigh Valley from 1900 until the end of World War I, producing 40-50 tons of horse and mule shoes daily. As demand for horseshoes fell, the Poughkeepsie-based Phoenix Horseshoe company bought up its competitors and diversified into commercial flanges and forgings. It concentrated production in the re-named Catasauqua plant, where it remains as the borough’s last link to its industrial heritage.

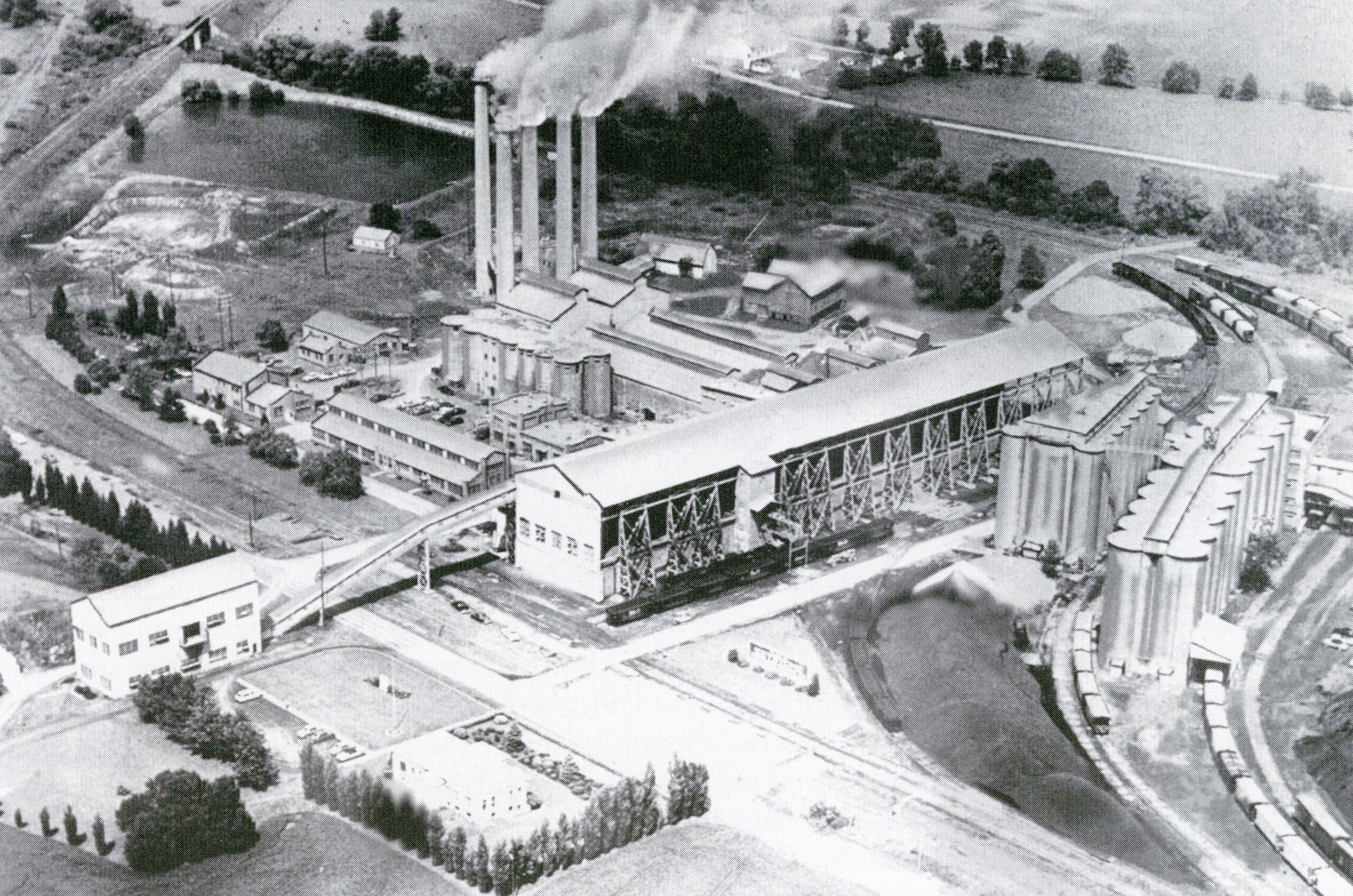

Nazareth Cement & Whitehall Cement

Both were founded in 1899 and are two of a handful of American cement mills that stayed in constant production for more than a century through multiple ownership and name changes.

The Nazareth facility, most recently called Lehigh Hanson, is now Heidelberg Materials. This connects the plant to another iconic cement company, Lehigh Portland Cement, which began in 1897. Lehigh was purchased by Heidelberg in 1997, and the German firm bought Hanson, an aggregates producer in 2007. Heidelberg bought the Italcementi firm Essroc, which was running the Nazareth plant in 2016, and renamed its US operations Lehigh Hanson. Now the corporation has adopted the name Heidelberg Materials and runs both the Nazareth plant and a former Lehigh Portland mill in Evansville, Berks County.

Whitehall Cement has most recently been owned by the French firm Lafarge, which merged with Holcim in 2015. The Holcim Group, as it became known in 2021, spun off its North American operations to Amrize, a building materials conglomerate, in July 2025. Under its new name, the plant in Cementon continues to produce the eco-friendly cement TerCem. The quarry west of the mill is the oldest continuously worked one in the Lehigh Cement District.

Hercules Cement

Located in Stockertown, now known as Buzzi Unicem USA, opened in 1916. It produces over a million tons of cement annually, and its 260-foot –tall pre-heater building is a local landmark along Route 33, especially when lighted at night.

Keystone Cement

Founded in 1928 in Bath by local cement legend Fred B. Franks. In April, 2025, the company announced that it has returned to independent operation, as it was not part of the sale of its former parent company, Spain’s Giant Cement Holding, to Heidelberg Materials. Keystone’s 540-foot-long kiln is the second largest in the US.

Mack Trucks

The Mack brothers moved their open-air tour bus building business from Brooklyn to Allentown in 1905 and began developing motor trucks. The move enabled them to build all the components of their trucks in one place. Their business grew steadily, then got a large boost from two brilliant engineers, Edward Hewitt and Alfred Masury, and the onset of World War I. The firm’s steady innovations, including diesel truck engines, power brakes, and a drive shaft helped it weather the economic gyrations of the mid-20th century. Mack has been a subsidiary of Volvo since 2000, which moved the corporate headquarters to Greensboro, NC. However, Mack Truck’s largest truck factory remains in Macungie and it is the fourth largest employer in the Lehigh Valley.

Crayola

Binney & Smith Company, the original name of Crayola, was founded in 1885 in New York as an industrial pigment firm. In 1900, the partners invented dustless chalk and also made slate school pencils. In 1903, Edwin Binney and his wife Alice developed colored wax crayons and Alice created the brand name by combining craie (French for “chalk”) and ola for “oleaginous” or “oily.”

Binney and Smith introduced the 64-crayon box with built-in crayon sharpener in 1958, bought the rights to Silly Putty in 1977, and added color markers to its line in 1978. Crayons in neon colors, sparkles and scents have been added, as well as various types of drawing and craft products. The company was acquired by Hallmark in 1984, and the corporate name was changed to Crayola in 2007.

From the beginning, Crayola crayons have been made in Forks Township, where about 90% of the world’s crayons are still made. By the early 1990s, the factory was one of the most–visited industrial plants in the US. Unable to manage the crowds, Crayola created a small demonstration exhibit called the Crayola Factory, paired it with other creative activities for children and joined the National Canal Museum in 1996 in Easton’s Two Rivers Landing. Housed in a renovated former department store on Centre Square, it became one of the top ten most visited places in Pennsylvania for the next decade. Now known as The Crayola Experience, it occupies the entire building.

Bradley Pulverizer

Founded in Boston in 1886 where it produced the Griffin Mill for grinding phosphate rock for fertilizer. Robert Lesley built American Improved Cement in Egypt that year and installed the first Griffin Mill to crush cement rock; it remained in service for thirty-five years. The Griffin Mill was rapidly adopted by the Lehigh District cement companies, which led Bradley to relocate its operations completely to a factory on S. 3rd St. in Allentown in 1914. Still at the same location and now an international business, its crushing and sorting products are used in over forty countries.

Cornell Cookson

Cornell Cookson has made rolling security doors and grills at its facility in Mountain Top since 1965, but its beginnings in New York date back to 1828, when the Cornell Iron Works began making plain and ornamental ironwork. In 1854, J.B. Cornell patented a method of joining metal slats for crank-operated shutters for store windows. A foundry built in the 1850s produced gun turrets and parts for the US Navy’s first ironclad ships. By the 1880s, the works was one of the biggest employers in New York City, and forged iron and steel work for buildings and the elevated railroads, as well as the base and stairs of the Statue of Liberty and ironwork and circular stairs for the Brooklyn Bridge.

Around 1910, the company moved away from forging and shifted back to expanding its rolling doors and security screens business. In 1931, it introduced the openwork steel security screens which are still in common use. In 1938, the Cookson Company was formed and provided steel service doors and covers for store and restaurant counters.

In 1965, Cornell moved all its production facilities to Mountain Top, while the Cookson Company moved to Gastonia, North Carolina and in 1990 to Phoenix, Arizona. Cornell Iron Works, still the largest American manufacturer of rolling doors and grills, acquired The Cookson Company in 2008, but maintains both manufacturing facilities.

Just Born

Sam Born, a Russian-born French candy maker opened a candy factory and store in New York in 1923. He put a sign in his shop window next to the candy he made fresh daily that read ‘just born.” His business thrived during the early years of the Great Depression, and in 1932 Sam decided to enlarge his operation by moving to an empty printing factory in Bethlehem. Three years later, Just Born bought a prestigious chocolate company, Maillard’s, but in 1940 entered the chewy fruit-flavored jellybean field with Mike and Ike in 1940, followed in 1950 by Hot Tamales.

In 1953, Just Born bought a Lancaster candy firm that made popular but very labor-intensive marshmallow chicks at Easter. Each piece was squeezed out of a pastry tube by hand and the whole process took more than a day. A year later, Sam’s son Bob invented a Peep production process that cut the time from birth to package to six minutes. An icon was born, and Just Born was on its way to becoming the tenth largest candy company in the US.

In 2003, Just Born saved the legendary Philadelphia brand Goldenberg’s Peanut Chews from candy oblivion and celebrated its centennial in 2017. Peeps celebrated their 100th birthday in 2023. No longer just an Easter treat, the puffy sweets now come in several flavors and colors and in seasonal versions like ghosts, turkeys, Santas and hearts. The Bethlehem plant is landfill-free, with a 97% recycle rate; 3% waste is turned into energy.

Who did we miss? Know of any more long-lived businesses in any of the five Corridor counties? Let us know at archives@nulldelawareandlehigh.org.

Join the Conversation!